See our work on social media:

Hear from a paving expert! Fill out the form below

How to Repair Driveway Concrete

Driveway Concrete: What to Know Before Getting Started

Driveway concrete: A cracked or damaged concrete driveway can be an eyesore, but the good news is—you don’t always have to replace the whole thing. With the right materials and techniques, you can repair your concrete driveway yourself and extend its lifespan. In this guide, we’ll break down everything you need to know about how to repair concrete driveway step by step.

Concrete vs. Asphalt Driveways

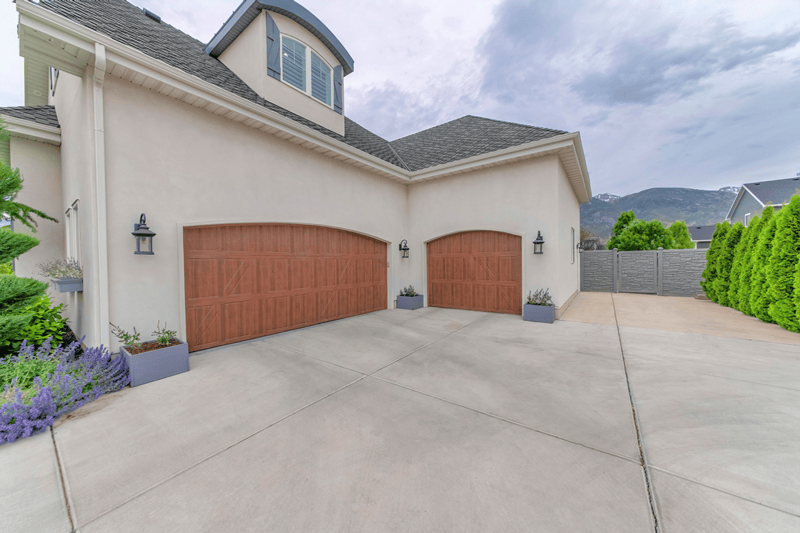

Before diving into repairs, let’s compare concrete and asphalt driveways. Concrete driveways are durable, long-lasting, and require less maintenance than asphalt. However, they can crack over time due to weather conditions, tree roots, and heavy vehicles. If you want a solid, low-maintenance solution, repairing a concrete driveway is worth the effort.

Concrete driveways also offer better heat reflectivity, making them a great option in warm climates. They don’t soften under high temperatures like asphalt, and they can be customized with different textures and finishes to enhance curb appeal.Benefits of Having a Concrete Driveway

Longer lifespan compared to asphalt

Handles heavy loads better

Low maintenance requirements

More visually appealing

Environmentally friendly (reflects heat rather than absorbing it)

Can be customized with stamping, staining, or polishing

Signs You Need to Do Repair Work

How do you know when your driveway needs repairs? Look out for these signs:

Cracks and Holes – Even small cracks can turn into bigger problems if left untreated.

Discoloration – This could be a sign of moisture damage.

Sunken Areas – Indicates foundation issues or soil shifting underneath.

Uneven Sloping – May cause drainage problems.

Water Pooling – Water collecting on the surface can lead to erosion.

Chipping and Spalling – Surface damage that could indicate deeper issues.

What Materials to Use for Repairs

Depending on the type of damage, you’ll need different materials:

Concrete patching compound (for small cracks and holes)

Mortar mix (for larger repairs)

Concrete bonding agent (to help new concrete stick to old surfaces)

Concrete sealer (to protect repairs from future damage)

Concrete lifting foam (for sunken slabs)

Wire brush and chisel (for cleaning cracks before repairs)

Key Factors to Consider Before Getting Started

Weather Conditions: Avoid repairing on rainy or freezing days.

Type of Damage: Small cracks require different treatment than sunken areas.

Curing Time: Some repairs take days to fully set.

Traffic Load: Heavier vehicles may require reinforced repairs.

Underlying Causes: Address tree roots or soil movement to prevent future cracks.

Step-by-Step Guide on How to Repair Driveway Concrete

1. Inspect the Damage

Before you start any repairs, take a close look at your driveway. Identify whether the damage consists of small cracks, large fractures, sunken areas, or tree root damage. This will help you choose the right repair method and materials.

If your driveway has extensive damage, you may need professional help. A simple patch won’t always be enough if the concrete is structurally compromised.

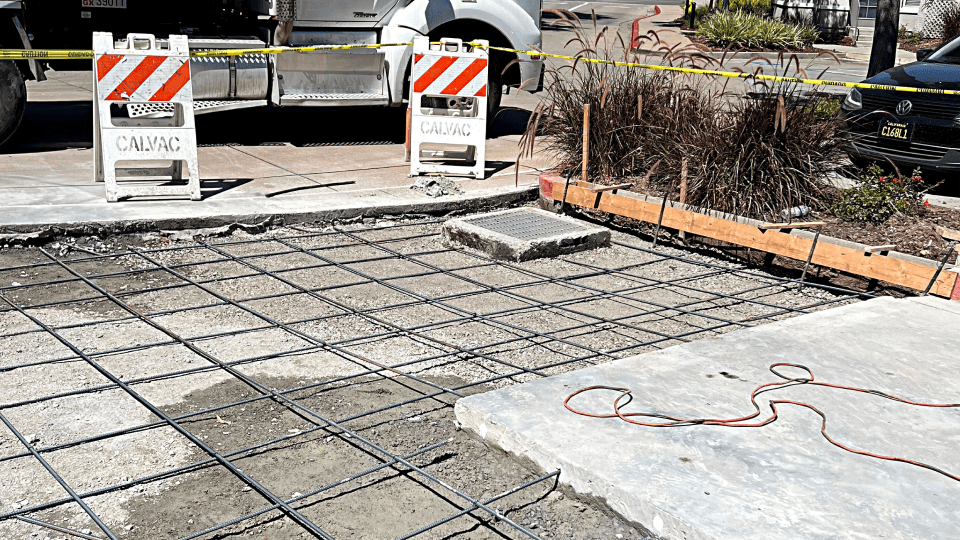

2. Clean the Area

A clean surface is crucial for effective repairs. Use a pressure washer to remove dirt, debris, and any loose concrete. A wire brush or a chisel can help dislodge stubborn pieces. Let the area dry completely before applying any repair materials.

Applying a concrete bonding agent after cleaning will ensure better adhesion for the repair materials.

3. Repair Small Cracks and Holes

Small cracks under 1/4 inch wide can be filled using a concrete patching compound. Simply apply the filler according to the product instructions and smooth it out with a putty knife. Allow sufficient drying time to ensure the filler bonds well with the surrounding concrete.4. Repair Large Cracks

Larger cracks require more effort to fix. First, undercut the edges of the crack using a chisel to create a wider base for better adhesion. Apply a concrete bonding agent, then fill the crack with a mortar mix, smoothing the surface with a trowel. Let it cure fully before using the driveway.

5. Repair Sunken Sections

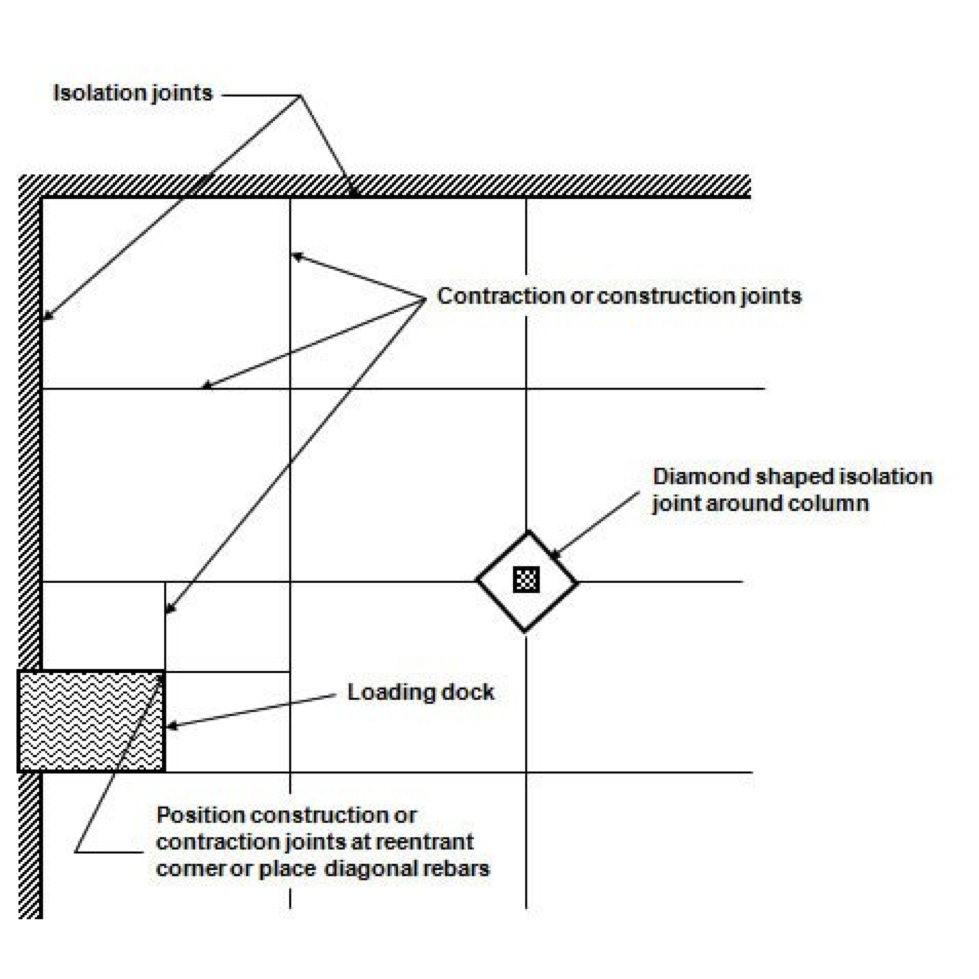

Sunken or uneven slabs are often caused by shifting soil beneath the concrete. One solution is using concrete lifting foam or mudjacking to raise the slab back into place. Alternatively, for severe cases, replacing the affected section may be the best option.

How to Repair Driveway Concrete Cracks

Cracks in concrete driveways can be repaired using patching compounds or mortar mix. Ensure the area is clean, apply a bonding agent, and fill the crack appropriately based on its size. Knowing how to repair concrete driveway properly can save you money and keep your driveway looking new.

For best results, apply a sealer over the repaired cracks to protect against future damage.

How Much Does Driveway Repair Cost

The cost of driveway repair depends on the severity of the damage. Small crack repairs can cost as little as $10-$50 for DIY solutions, while professional concrete lifting or slab replacement can range from $500 to $2,500, depending on the extent of the work required.

Concrete Driveway Repair: Get Started Today

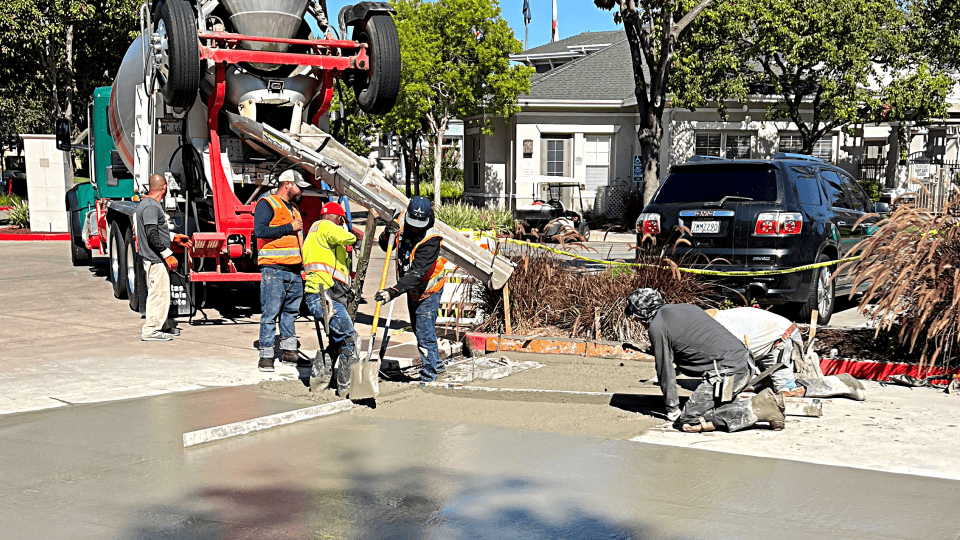

Now that you know how to repair concrete driveway, take action before small cracks turn into costly damage. If the damage is beyond DIY repair, consider hiring professionals like Calvac Paving to ensure the job gets done right.

Concrete driveway repair is an investment that protects your home’s value and appearance. By keeping up with maintenance and acting quickly when you notice damage, you’ll keep your driveway in great condition for years to come.

Learn About About Calvac Paving: FAQs

What services does Calvac Paving offer?

Calvac Paving specializes in asphalt and concrete paving, repair, and maintenance services. They provide solutions for residential, commercial, and municipal projects.

Where is Calvac Paving located?

Calvac Paving is based in San Jose, California, and serves the surrounding areas, providing top-tier paving and repair solutions.

Does Calvac Paving handle both small and large projects?

Yes! Whether it’s a small driveway repair or a large commercial parking lot resurfacing, Calvac Paving has the expertise and equipment to handle projects of all sizes.

How can I request a quote from Calvac Paving?

You can visit Calvac Paving’s website and fill out their contact form, or give them a call to discuss your project and receive a customized quote.

How long has Calvac Paving been in business?

Calvac Paving has been serving the Bay Area for over 45 years, making them a trusted name in the paving industry.

What makes Calvac Paving different from other paving companies?

Calvac Paving stands out due to its commitment to quality, customer satisfaction, and long-term durability. They use high-quality materials and proven methods to ensure every project lasts for years to come.

Does Calvac Paving offer eco-friendly paving solutions?

Yes! Calvac Paving implements environmentally friendly practices, including sustainable materials and energy-efficient processes, to reduce their impact on the environment.

How soon can I use my driveway after Calvac Paving repairs it?

The drying and curing time for repairs depends on the materials used. Typically, you can walk on the driveway within 24 hours and drive on it within 48-72 hours. Your paving professional will provide exact guidelines for your specific repair.

Can Calvac Paving help with preventive maintenance for my driveway or parking lot?

Absolutely! They offer sealcoating, crack filling, and other maintenance services to keep your concrete driveway or asphalt pavement in excellent condition and extend its lifespan.

By choosing Calvac Paving, you’re partnering with a company that prioritizes quality and long-lasting results. If you’re in need of professional concrete or asphalt repair, reach out to them today!