See our work on social media:

Maintenance Monday: Protect Your Asphalt—A 2024 Update on Our 2018 Case Study

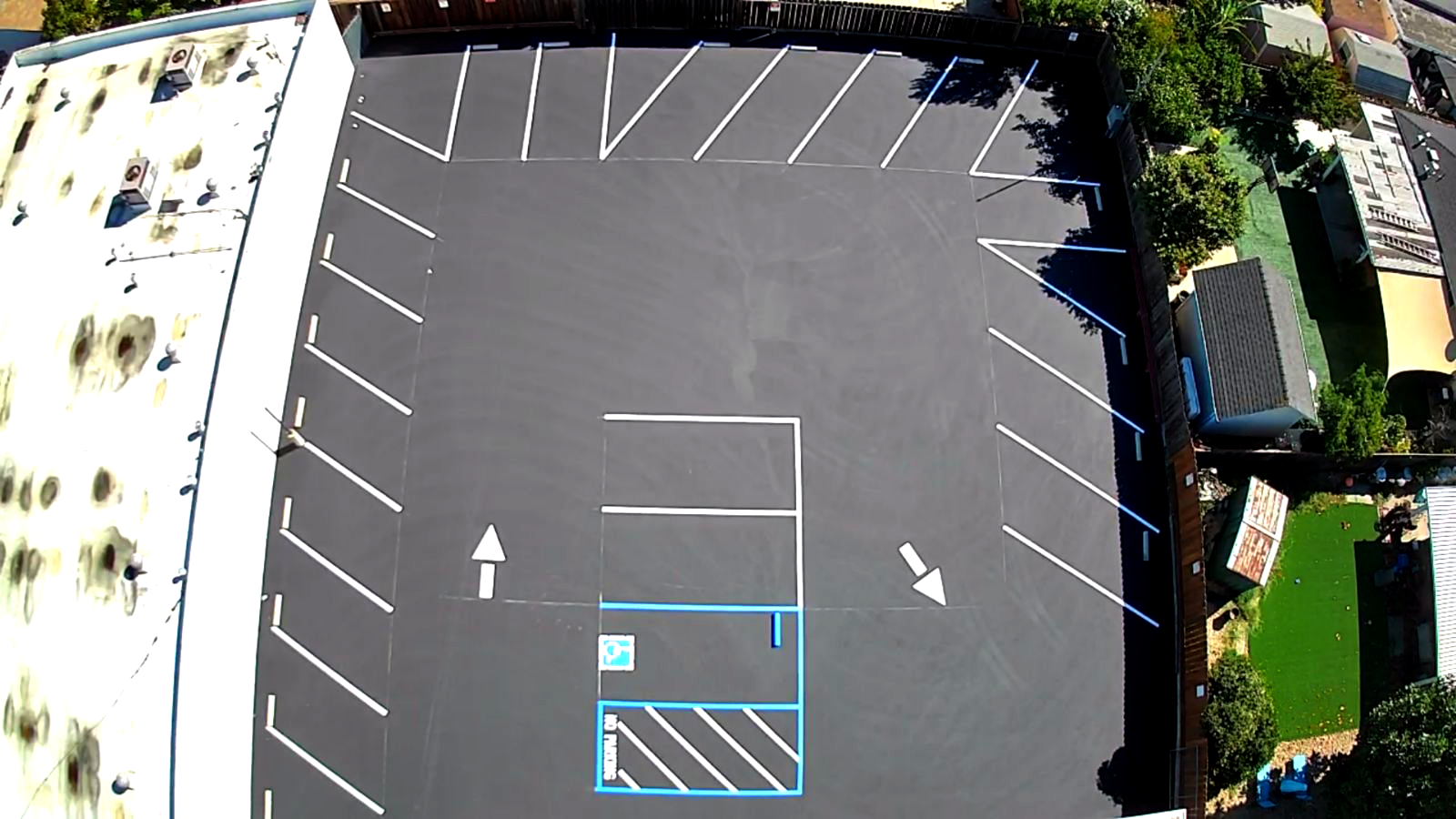

Explore how strategic maintenance and timely sealcoating have preserved our asphalt project at PEL Learning Center - Hayward since 2018, proving its worth as a smart, long-term investment.

Back in 2018, we embarked on an ambitious asphalt replacement project at PEL Learning Center located at 24150 Hesperian Blvd., Hayward, CA. Not one crack has appeared to date, a testament to the quality of the installation and materials used. Despite the sealcoat being overdue, the pavement remains in excellent condition. As we revisit this success in 2024, we emphasize the crucial role of ongoing maintenance and timely sealcoating in extending the asphalt’s lifespan.

Protecting Your Asphalt: The Importance of Regular Sealcoating

Asphalt may be tough, but it’s not invincible. Regular exposure to UV rays, water, and oil can degrade its structure. That’s why consistent sealcoating is essential—it serves as a shield against these elements, preventing damage and maintaining the integrity of the pavement. Although our sealcoating was overdue, applying it has significantly boosted the longevity of the surface, enhancing its appearance and positively impacting customer impressions of the property.

Updated Project Details

The integrity of the asphalt laid in 2018 remains intact, showcasing the enduring quality of our initial work. Recently, we’ve reinforced this durability with a specialized sealcoating regimen:

- Preparation: The asphalt surface was meticulously cleared of all debris.

- First Coat Application: We applied a robust sealant mixed with two pounds of sand per gallon, enhancing traction and durability.

- Second Coat Application: A second sealcoat layer was added to ensure comprehensive protection and enhanced resilience.

Benefits of This Approach

- Extended Lifespan: The dual-layer sealcoating has effectively increased the pavement’s expected life. Applying two coats of sealer instead of one coat leads to a superior finish. These water-based sealers cure and form a protective film primarily through the evaporation of water.

- Cost Efficiency: For high-traffic commercial parking lots, the enhanced durability provided by regular maintenance significantly reduces the frequency and severity of necessary repairs. This extended lifespan of the pavement not only cuts long-term expenses but also minimizes disruptions in busy areas, ensuring a smoother operation and a more consistent customer experience. By investing in preventative care, businesses can substantially decrease the overall cost of ownership and maintain the aesthetic appeal of their property, boosting its value and appeal.

- Aesthetic Enhancement: The sealcoating, complemented by precise striping, has revitalized the asphalt’s appearance, enriching the overall look of the property. This combination not only enhances the visual appeal but also improves navigational clarity, making parking areas more organized and visually striking.

Conclusion:

Our 2018 project at PEL Learning Center in Hayward stands as a prime example of how diligent maintenance and regular sealcoating are not just beneficial but essential for prolonging the life of asphalt paving. With the right care and strategic interventions, such as those implemented at 24150 Hesperian Blvd., asphalt becomes a smart investment in the longevity of a property’s infrastructure.

Call to Action:

Don’t let your asphalt suffer—ensure its longevity with our expert sealcoating services. Contact us today to keep your pavement in prime condition for years to come, just as we have since 2018.